Peanut grades have gone up some in the last week for our area, but not for the state. Cotton picking is slow to start but some bales have been harvested. Forecasts are still showing little to no rain over the next 10 days and temps are starting to drop off some now.

Topics In this Update:

- Defoliation Update (Dr. Camp Hand, UGA Cotton Agronomist)

- Estimating Harvest Losses for Peanut (Dr. Wes Porter, UGA Precision Ag Specialist)

- Ext Precision Ag and Irrigation Blog Post (Dr. Wes Porter, UGA Precision Ag Specialist)

- 2025 Row Crop Disease Update 20 October (Dr. Bob Kemerait, UGA Plant Pathologist)

- Talkin’ Cotton Podcast (UGA Cotton Team)

- All About the Pod Podcast (UGA Peanut Team)

Defoliation Update (Dr. Camp Hand, UGA Cotton Agronomist)

Had to run back in the house this morning and grab a jacket – starting to get a little cool out there and we may need to think about changing up recipes in the not so distant future.

Statewide, looks like clear weather with highs in the 70s, lows in the 40s to 50s. Beautiful weather for defoliation and harvest.

In terms of rates, below is what I’m thinking:

Thidiazuron – 2 to 4 oz/acre – all dependent on how quickly your growers will to the field for harvest. I think this product improves the efficacy of the entire tank so I don’t want to completely remove it just yet.

Folex – 12 to 14 oz/acre – can back off to 10 on warmer days this week but higher rates are going to be necessary as temps go down.

Ethephon – 32 to 42 oz/acre – cooler temps, higher rates.

We are getting to the point of the year where I may consider a Ginstar/Adios/Cutout + Ethephon tank-mix – I’d be looking at probably 6 to 7 oz/acre of Ginstar this week (I’d go up to 8 but some people don’t like that – if you have growers that aren’t scared 8 is a great rate).

Of course PPO herbicides are still an option and worth considering in certain situations – if you have questions about that please let me know.

As always if something else comes up feel free to give me a shout.

Also – reminder that every deer hunter in GA can legally harvest 10 does… get out there and do your part!!!

Estimating Harvest Losses for Peanut (Dr. Wes Porter, UGA Precision Ag Specialist)

By Wesley Porter, Scott Tubbs, John Bennett, Seth McAllister, and Sarah Beth Thompson

Unfortunately, we have reached that point in peanut harvest that it has gotten hot and dry for an extended amount of time. This weather can have negative effects on the peanut inversion and harvest process. I have started receiving calls about estimating peanut harvest loss. Thus, I worked through a few resources and compiled the following information.

While there is a lot of information out there on harvest losses for peanut and a few ways to estimate it, some of the methods can be a bit confusing. Hopefully, this post can help to clarify it. Losses during peanut harvest are common and can be caused by improper setup, operation and/or performance of the harvest equipment. Some losses can also be attributed to the field and crop conditions at harvest. Excessive losses can significantly reduce peanut yields and profits if not managed or reduced during harvest. While harvest losses cannot be not completely eliminated, it is always good to understand the level of losses so appropriate adjustments to harvest equipment settings, operational parameters or harvest decisions can be made to keep these losses to the minimum.

In the roughest and most simple check, from a few sources you can estimate that each pod lost per row foot is equal to about 40 lb/ac in Runner type peanuts (and 60 lb/ac in Virginia type). While this gives you a quick estimate, I strongly recommend measuring out a known area and collecting the pods from that area, checking them for actual sound mature kernels, pops, etc. This year we have been observing more pods on the ground making it appear like there are a lot of lost peanuts, it is critical that you verify this.

Peanut harvest losses can be estimated from the number of pods left on the ground after combining through the few simple steps below:

1. Measure and mark a sample area behind the combine using a tape measure and some flags or alternatively you can also use any rectangular or round sampling device as shown below. Note that the larger the measuring area or the device, the more accurate the loss estimation will be. Loss estimations are also more accurate when performed across the entire width of the windrow than in a smaller area. Do your best not to bias this loss estimation by selecting a point in the windrow that you just see a lot of pods.

2. Record the length and width of the marked section or the sampling device and calculate the area in square feet. Remember that if you are measuring a certain length of the windrow, you are working with two peanut rows and a sample width of 72 in. or 6 ft based on 36-in. row spacing. Again, your exact row spacing may vary slightly, adjust accordingly.

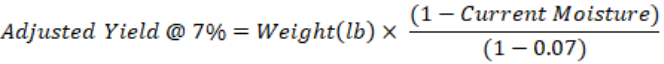

3. Make sure to account for moisture content in the pods (formula below)

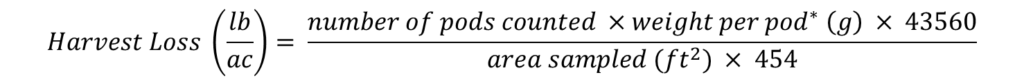

4. Within the selected area (whether marked using flags or of the sampling device), count the total number of pods and use the formula below to estimate the harvest loss in pounds per acre. Keep in mind that not all pods are mature harvestable peanuts, you should do a check to see how many are mature harvestable pods and how many are pops and adjust accordingly. Ideally, you need to sample in multiple different areas (at least three to five) and compute an averaged value for the number of pods counted from all the samplings. Use the weight per pod from the values provided below for Runner and Virginia peanuts.

*The average weight per pod is estimated to be 1.8 g for Virginia type peanuts and 1.2 g for Runner type peanuts (varies by cultivar and moisture content, adjust accordingly for more accuracy)

43560 is the conversion factor for square feet to acres and 454 for grams to pounds.

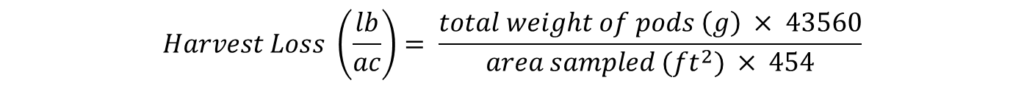

5. If you want to be more precise, rather than using average pod weight based on peanut type, you can weigh the total number of pods (in grams) collected within the sampled area and use the formula below to obtain a better estimate of harvest loss. (It does not account for pod moisture, which is not easily measured in-field. Adjust accordingly for most accurate values.)

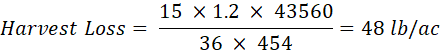

Example Harvest Loss Calculation

If the average number of pods counted in three, 6 ft wide by 6 ft long sections were 15, then using the sampled area as 36 ft2 and assuming Runner peanuts in the formula from step 3, the total harvest losses would be 48 lb/ac.

This can become difficult if you are collecting this information from a windrow that is not the entire width of the original harvest area. In this case, it’s best to either take the entire width of the new windrow from the harvester and assume that it is the total harvest width (6 rows or 18 ft in most cases) or scale a smaller area. It should also be understood that some of the loss can be coming from either the header or the entire machine. The wider the area you collect the more accurate.

Once you have determined losses, it is time to start considering if you should make any combine adjustments. Below are a few other resources for estimating losses:

Peanut Yield Estimator – Clemson

If you have more questions about peanut harvest loss calculations, or how to delineate the difference between digging, header, or entire harvest loss, please reach out and we can discuss it.

Ext Precision Ag and Irrigation Blog Post (Dr. Wes Porter, UGA Precision Ag Specialist)

This post is not directly related to agents outside of the SW and specifically the Flint River Basin but I still encourage you to read and share if you would like. All of this information is captured more in-depth in the post, but one of the modified Floridan Aquifer Permits triggered to stop withdraws on Friday. It did recover over the weekend, but this is critical for everyone to understand the impacts of the lack of rainfall and aquifer recharge specifically on irrigation in this case.

Please read through this post and let me know if you have any questions. Share as you see fit.

2025 Row Crop Disease Update 20 October (Dr. Bob Kemerait, UGA Plant Pathologist)

Things to do in my wheelhouse of diseases and nematodes continues to wind down. The remaining items, as I have mentioned before, are to:

- Pull soil samples for nematode analysis, where appropriate

- Document issues with disease and nematode control so as to fix in 2026

- Diagnose problems that occurred in 2025 so as to find solutions in 2026. Waiting until March to try and figure out “what happened” probably will not work too well.

- As reminded by Dr. Barry Tillman, peanut breeder at the University of Florida, it not legal to save seed for some of our newer varieties. No doubt it is ok to say Georgia-06G and older varieties, but care should be taken before saving seed from newer cultivars.

Talkin’ Cotton Podcast (UGA Cotton Team)

Below is a link to this week’s episode of the Talkin’ Cotton Podcast. As always, distribute as you see fit and if you have any questions don’t hesitate to reach out.

https://www.buzzsprout.com/2350262/episodes/17988475

All About the Pod Podcast (UGA Peanut Team)

Episode 32, Season 3 — 1st week of October – Harvest Continues along with Management of Lates Season Disease and Insects

In this episode, Scott Monfort, Mark Abney, Scott Tubbs, Eric Prostko, Albert Culbreath, and Kaelyn Morgan discussed the impacts of recent weather patterns, along with leaf spot and insects on harvest and the late-planted peanut crop. Please contact your local UGA extension agent if you have questions or need assistance.

EPISODE 33, Season 3

In this episode, Scott Monfort, Mark Abney, Scott Tubbs, Eric Prostko, Albert Culbreath, Wes Porter, Taylor Singleton, and Kaelyn Morgan discussed the current weather conditions, insect & disease issues, yields, and grades. The group also talked about cover crops. Call your local UGA extension agent if you have questions or need assistance.

EPISODE 34, Season 3

In this episode, Scott Monfort, Mark Abney, Scott Tubbs, Eric Prostko, Bob Kemerait, Wes Porter, Bailey Abney, and Kaelyn Morgan discussed the changes in weather conditions this week along with the late planted crop as it relates to yields and grades. Call your local UGA extension agent if you have questions or need assistance.