Thiago Nogueira Marins, Ph.D. Candidate

Sha Tao, Ph.D., Associate Professor, stao@uga.edu/706-542-0658 Department of Animal and Dairy Science, UGA

It is widely recognized that heat stress causes negative impact on the performance, health, and welfare of dairy cattle. The levels of heat experienced by dairy cows are influenced by production systems and management practices to which cows are exposed. Therefore, understanding environmental conditions on the farm-level and implementing cost-effective heat abatement strategies are essential to maintaining productivity and maximizing economic returns in dairy operations.

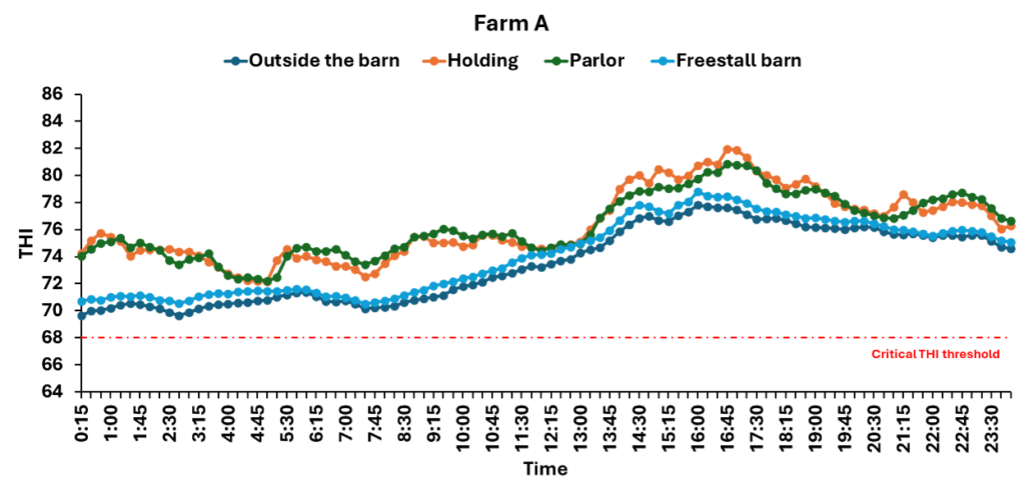

In the last issue of Georgia DairyFax Newsletter, we discussed the effective use of temperature-humidity index (THI) as an index to monitor heat stress. When daily average THI reaches or exceeds 68, milk yield starts to decline, and cooling methods should be implemented. We also discussed that heat stress should be continuously monitored, especially in regions with high temperatures and humidity, such as the southeastern United States. The data obtained from the nearest public weather station is readily available for evaluation of heat stress to guide decision-making in enhancing animal comfort. However, specific farm-level factors, such poor ventilation, can amplify heat stress leading to more adverse effects. For instance, in a heat stress audit conducted on dairy farms in Georgia during a summer, we evaluated the THI at different locations on the farm. As shown in Figure 1, both Farm A and Farm B had higher THI values at the holding area and milking parlor compared to free-stall barns particularly during the day. These results demonstrate that a deep evaluation of the environment at different locations of a farm is necessary.

In addition to environmental parameters, animal-related measurements can be effectively used to identify and assess the severity of heat stress in individual dairy cows or groups, offering a more comprehensive approach compared to environmental parameters alone. In dairy cattle, physiological, behavioral, and production-related signs can be used to identify animals suffering heat stress. These parameters include, but are not limited to, increased respiratory rate (panting or open-mouth breathing, excessive salivation and drooling), decreased milk production, reduced feed intake, increased water consumption, restlessness or agitation, and the increased body temperature. The change in body temperature has been used for the detection of diseases and a heat event. Under heat stress conditions, disrupted thermal balance increases heat load, leading to a rise in body temperature. To facilitate heat dissipation, in addition to providing shade, a primary cooling strategy commonly used on dairy farms is evaporative cooling including forced ventilation with fans and water-based methods such as soakers, sprinklers, or showers. The combination of airflow and direct wetting enhances heat dissipation and helps cows regulate their body temperature more efficiently.

Cooling settings can be different depending on farm infrastructure, investment capacity, and management practices. However, it is essential to ensure the effectiveness of cooling for a cow to relief body heat and mitigate the negative impacts of heat stress. In a free stall barn system, effective cooling in holding area/milking parlor and the free-stall barn is essential for heat stress management.

Holding area/milking

Holding area is the most hostile area on a dairy farm for heat stress management, and the effectiveness of cooling can significantly impact cow comfort, productivity, and overall welfare. Thus, an efficient milking process should be adopted to avoid extended standing in the holding area. In the holding pen, cows stand closely together, raising the surrounding temperature and limiting their ability to dissipate heat. Without cooling, the body temperature of a cow rises significantly. In contrast, with effective cooling, the holding area can be an excellent opportunity to cool cows, especially when cooling is inadequate in free-stall barns.

In addition to providing shade to protect against solar radiation, ventilation is critical for heat abatement, which includes both natural ventilation and forced ventilation. In an enclosed holding area, natural ventilation may be insufficient causing elevated ambient temperature, for instance, the THI of the holding area of farm A was always higher than the THI of the free-stall barn as shown in Figure 1. In this situation, it is more important to provide high-capacity fans for consistent air flow and effective soaking to optimize evaporative cooling.

The time spent in the parlor varies depending on cow flow, udder preparation, and milking process, but proper cooling may be considered. In the parlor, water may not be applied due to the concern with increased mammary infection. However, using fans to improve airflow may further abate heat stress during milking process. Additionally, the use of showers in the exit line to soak the skin and hair coat may be adopted as a method to prevent further increases in body temperature, especially for cows who need to walk long distance from the parlor to the barn.

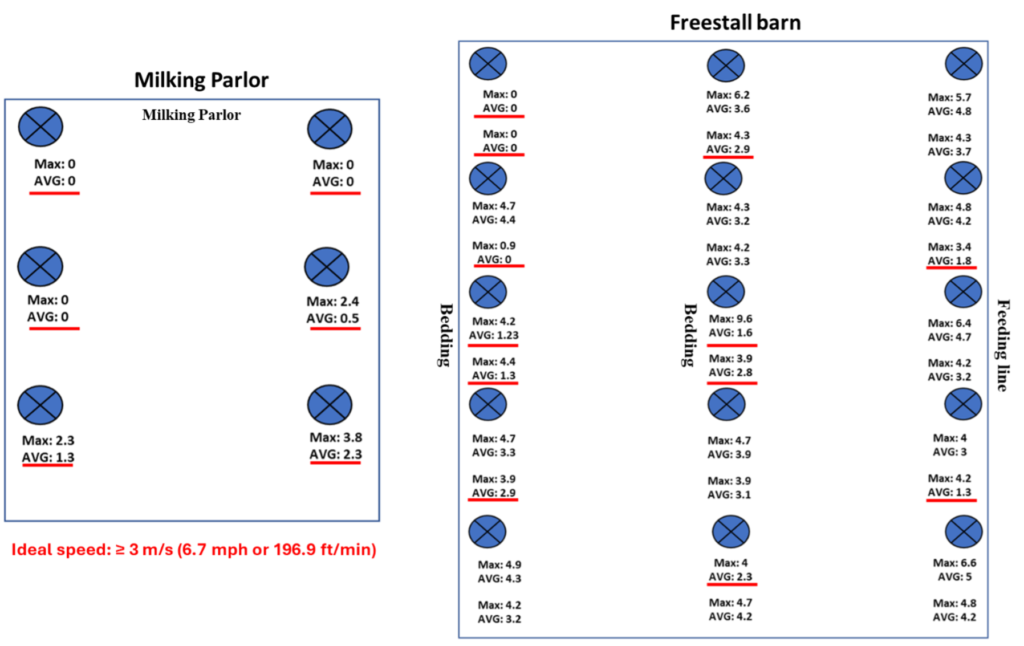

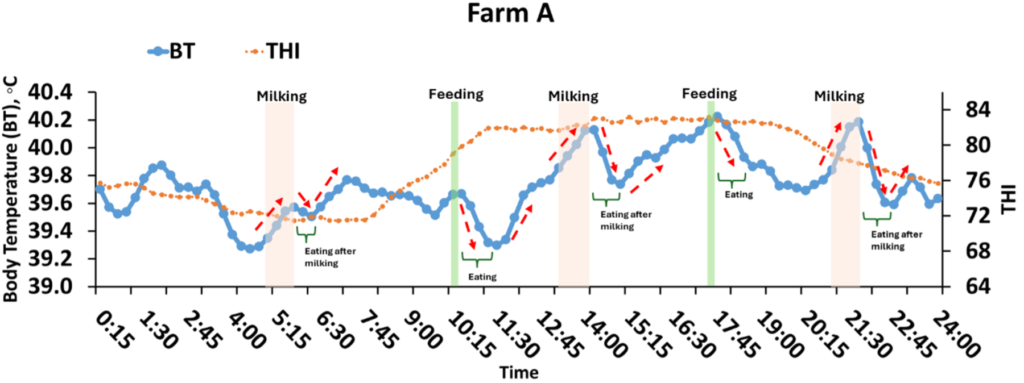

In a heat stress audit conducted in a commercial dairy farm (Farm A), we monitored the body temperature using a thermometer sensor (iButton) attached to a blank (progesterone-free) intravaginal implant every 5 minutes. Farm A had an enclosed holding pen, and there were fans and soakers in the holding area, but not in the milking parlor. Cows were milked three times a day and fed twice a day. In the holding area, soakers were not working adequately because most of the nozzles were dirty and clogged, consequently not wetting cows properly. Additionally, fan air speed was recorded using a portable handheld anemometer. As shown in Figure 2, all the fans in the holding area did not achieve an ideal air speed (constant air of ≥ 3 m/s). This is mainly because fans were not installed properly (adjacent to the ceiling which blocks air flow) and inadequate maintenance (no regular cleaning). As a consequence, cows had significantly increased body temperature in the holding area and milking parlor (Figure 3). And a more pronounced increment of body temperature was observed in the afternoon milkings, which coincidences with the greater THI compared with morning milking. These emphasize the importance of proper cooling in the holding area and milking parlor.

Thus, farms need to incorporate environmental data such as THI, the information of cooling equipment conditions, and the body temperature of cows to evaluate and improve the effectiveness of the cooling system in the holding area. Particularly, farms need to pay attention on the cleaning and maintenance of and water nozzles, and adjusting the location and angles of fans to provide direct and sufficient air flow to cows. In addition, fans may be installed in the milking parlor to provide additional cow comfort.

Free-stall Barn

Cows spend most of their time in the barn, thus effective cooling plays a critical role in maintaining cow comfort, productivity, and health during summer. Using a combination of fans and water system over the feed line effectively reduces heat load of the cows. Fans should provide sufficient and direct airflow on the cow level along the feed line, and the quantity and angle of fans should be adjusted to achieve this goal. The water-based cooling systems along the feed line including soakers, sprinklers, or misters are needed to wet the cows and facilitate evaporative cooling.

This is particularly important to lower the body temperature during the daytime when ambient temperature exceeds the cow’s surface temperature. Additionally, fans over the bedding area are a tool to provide additional cooling and increase cow comfort while cows are lying down. However, cooling using fans can only be effective when the ambient temperature is below the cow’s surface temperature, such as the nighttime. It is important to mention that sufficient access to water troughs with cool and clean water is critical to help cows cope with heat stress.

During our heat audit, we monitored the speed of fans in the free-stall barn of Farm A. We observed that almost all fans located over the bedding area did not provide sufficient air speed to cows. In contrast, most of the fans over the feed line were working properly (Figure 2). The soakers were installed over the feed line, but we observed that a few nozzles were clogged. Cows were exposed to heat stress conditions as the THI was greater than 72 during most of the day, peaking in the afternoon with THI higher than 80. The average body temperature decreased following milking and feed delivery when cows spent most time eating and experiencing cooling over the feeding line. However, the body temperature gradually increased following eating, possibly because cows started to move and lie down in the stalls. These data indicate the effectiveness and importance of feed line evaporative cooling system to maintain cow body temperature. However, the increment of body temperature following eating may suggest that cooling only by fans are not sufficient to maintain or further reduce cow body temperature. This may be due to 1. The fans over the freestalls cannot provide enough air speed or flow for cow cooling when cows are standing and lying down in the bedding area, and 2. The forced ventilation alone is not sufficient to cool cows, especially when the air temperature exceeds cow surface temperature.

Cooling systems, including evaporative cooling systems, have been widely used in dairy farms, but if cooling systems effectively cool cows on a dairy farm are rarely studied. In other words, implementation of cooling systems doesn’t mean effective heat abatement. Therefore, a holistic evaluation of the cooling system is needed to identify areas where improvements are needed. Addressing any issues identified, especially before the summer, will ensure cow comfort and maintain productivity and health during heat stress. Proper maintenance, repair, and cleaning of all fans and water nozzles are essential for effective cooling. Further, additional cooling approaches should be developed to enhance heat abatement when cows are in the bedding areas.

Figure 1. THI throughout the day in different locations at Farm A and Farm B.

Figure 2. Average (AVG) and Maximum (Max) air speed (m/s) in front of the fans located in the holding area and inside the freestall barn. Measurements were taken at close and far distances from the fan, including standing at the feed line and lying down on the bedding. Measurement time: 30 seconds at each location. The red underline indicates the wind speed did not meet the desired speed (3 m/s).

Figure 3. The average body temperature of multiparous late lactation Holstein cows (n = 13) and THI values throughout the day. The red arrows show an increase or decrease in body temperature.

*Unpublished Data