Simerjeet Virk, Extension Precision Ag Specialist, UGA & Wesley Porter, Extension Precision Ag and Irrigation Specialist, UGA

For peanut growers, this is a perfect time to start inspecting their planters and perform any required maintenance on components to ensure peak planter performance during field operation. Planting mistakes due to improper setup and maintenance can lead to costly emergence penalties that impact yield potential. Growers can access and utilize a planter checklist available here PlanterChecklist_C1231.pdf (uga.edu), and make sure to go through each planter component carefully to ensure its proper setup and functioning. Please remember that this checklist provides some general guidelines for inspection and setup of different planter components but the exact setup for each planter component will depend on your planter type, crop being planted (peanuts in this case), and the field conditions. Therefore, make sure to spend some time and verify the in-field planter performance by consistently performing checks in the field during planting, and also make any required adjustments as soil or field conditions change among or within the fields. Here are few key points to remember to check planter performance in the field when planting peanuts, and ensure that each planter component is optimized for the soil type and field conditions at planting:

1.Seed depth– Recommended seed depth for planting peanut is 2.0 to 2.5 inches. Verify seed depth before planting both on a hard surface and in the field. Mechanical seed depth settings can vary among the row-units on the same planter so make sure to check planted seed depth for each row-unit and make necessary adjustments as needed.

2.Downforce – Planter downforce is important to achieve target seeding depth so make sure the downforce system (mechanical or active) is set to apply enough downforce on each row-unit. A minimum downforce of at least 100 lbf is recommended for planting peanuts. Remember these downforce requirements will vary with soil type, texture and moisture so make sure to make those adjustments as field conditions change from one field to another or within the same field.3.Seeding Rate – Recommended seeding rate for peanuts (6 to 7 seed/ft) is higher than the nominal seeding rates for corn and cotton (usually around 2 to 4 seed/ft) which requires a seed meter to singulate seeds at considerably higher speed (rpm) even at normal planting speeds. Therefore, it is recommended to check seed singulation on a test stand for seed meters before planting at your preferred seeding rate and planting speed. Unnecessary skips or multiples will result in poor or uneven stand establishment which can further impact yield if stand is reduced significantly. Peanut seed is also larger than corn and cotton seeds and requires higher vacuum, so make sure to adjust the vacuum appropriately to avoid skips and multiples.

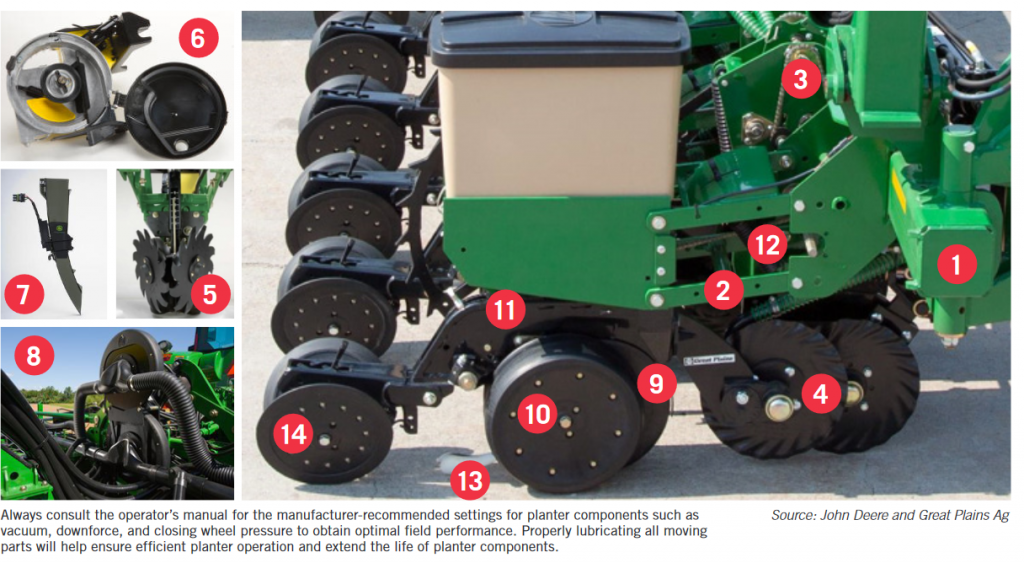

4.Seed Placement and Seed-to-Soil Contact – Proper setup and functioning of row-cleaners (when planting in conservation systems), double-disc openers, gauge-wheels, and closing wheels for prevalent field conditions is critical to attain adequate seed placement and proper seed-to-soil contact. Make sure that the double-disc openers are creating a true V-shape furrow, gauge-wheels are running tightly (but not excessive) against the opening-discs, and closing wheels are aligned perfectly behind the planter and set to apply adequate pressure on the furrow.

5.Planting Technology – Issues with planting technology in middle of the planting season can cost significant time and money. Make sure to perform a thorough and timely (at least a week or more) inspection before planting to check status and functioning of all technology components including GPS, seed monitor, wiring harnesses, seed tube sensors, rate control module, electric seed meters, and active downforce system as well as for any subscription or latest firmware updates for the GPS and seed monitoring display. Lastly, remember that planter settings can vary from one planter to another so make sure to check and follow the settings recommended in the operator’s manual while using the planter checklist and points outlined above to set up your planter for peak performance.