The process of preserving quality forage is an art. In this process there are factors that we cannot control, i.e. the weather, but the type of bale wrap we choose can be controlled. Many times, our choice of bale wrap comes from our personal preference or the machinery that is available.

When bales are stored outside, there are some wraps that perform better than others. If you based your wrap decision strictly on cost, twine would win every time. Net wrap costs an additional $0.30 to $0.50 per bale, but what you save on material cost by using twine you may lose in the quality decline of your hay. This loss begins during the wrapping process. When comparing net wrap and twine, wrapping bales in net wrap is faster than wrapping in twine. According to a study in Wisconsin, a net wrap baler can wrap up to 32% more bales than twine because of the decreased number of rotations. The reduction in rotations also decreases the amount of dry matter loss during this process.

After all the time and effort invested to make quality bales, the last thing we want is to lose quality during storage. On average, 20-45% of dry matter loss can occur during the storage process. While we all know that the best storage for hay is under a shelter and out of the weather, this may not always be an option. Choosing the right hay binding can curtail dry matter loss when hay must be stored outside.

Research out of Kentucky has shown that when bales are stored outside, twine results in the most dry mater loss, followed by net wrap and plastic having the least amount of loss. With net wrap or plastic sleeves, dry matter loss is at 5-8% the first year and an additional 2-5% percent the following year. This is compared to a 5% loss of dry matter loss the first year and little thereafter if the hay is stored under a shed.

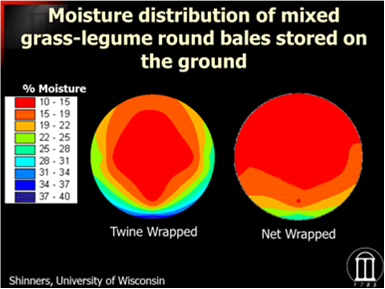

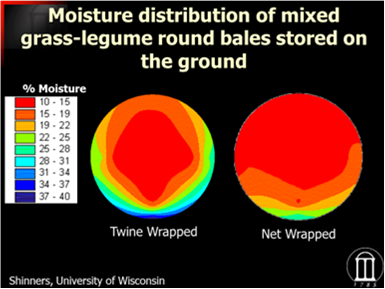

Dry matter losses during storage result from plant respiration, microbial activity, and weather deterioration. “Weathering” is partially a physical process. Some of the dry matter loss that occurs during outside storage is caused by leaching, the dissolving and removal of nutrients by the passage of rain water over the surface of and through the bale. Net wrap sheds water better than twine when stored outside and also holds its shape better. This allows for less deterioration of the bale through weathering.

While plastic wrap is mostly associated with baleage, it can be used to protect dry hay as well. Twine wrapped bales may benefit economically from a couple wraps of plastic when stored outside. The purpose of the plastic wrap is to shed rain and keep the hay from absorbing moisture from the ground. Typically, you will want to wrap the bale with 2 layers. Black plastic is cheaper, draws more heat, and will help evaporate condensation within the bale. A couple of inches of white mold may develop on the outside of the bale, but this loss to mold is less than the weather loss.

There has also been interest in John Deere’s B-Wrap. This system only works with John Deere series 7, 8 and 9 balers and is an additional attachment to the baler. The cost is higher per bale than net wrap, around $5-$7, but it may achieve losses similar to being under a shelter. Microscopic pores allow for moisture to escape as compared to plastic. B-Wrap also sheds water as well as prevents ground moisture from being absorbed into the bale.

There are many options for bale wrap on the market. Hay storage options, time and dry matter loss need to be considered when choosing a wrap. Each wrap has its pros and cons and it is up to you to decide which best fits your situation.