Cage-free henhouse and dust

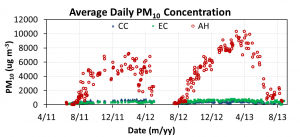

Concerns over animal welfare have led to pledges of sourcing only cage-free eggs by many U.S. food retailers and restaurants such as Walmart and McDonald’s by 2025 or 2030. According to the current number of pledges, it would take more than 70% of the current US layer inventory to meet the pledged demand by 2025. In November 2018, California made cage-free hens a state law by requiring that all eggs come from cage-free hens by 2022. Compared to a conventional cage system, cage-free hen housing offers birds more space and opportunities to practice their natural behaviors such as dustbathing, foraging, and perching, etc. One environmental challenge posted by cage-free housing is high dust or particulate matter (PM) levels, especially during cold weather when the house has limited ventilation. Based on two years of continuous measurement conducted by Iowa State University during a Coalition for Sustainable Egg Supply (CSES is made up of leading animal welfare scientists, academic institutions, non-government organizations, egg suppliers, and restaurant/foodservice and food retail companies) project, researchers found that the PM10 (particulate matter with size smaller than 10 micrometer in diameter) levels in cage-free houses were 6-9 times higher than conventional cage manure-belt and enriched colony houses (as shown in fig. 1).

Figure 1. Dust level in three different systems (CC- conventional cage, EC- enriched colony, AH- aviary house).

Sources and potential risk of high dust level

Dust concentrations and emissions are high in cage-free houses due to accumulation of floor litter (a mixture of hen manure and bedding materials), bird activities, and the dry litter condition (e.g., 10-15% floor litter moisture content in Iowa). Higher levels of dust in cage-free house air can carry more airborne microorganisms and endotoxins which, once inhaled, may trigger respiratory diseases to animals and/or their caretakers. The PM10 and PM2.5 (particulate matter with size smaller than 10 and 2.5 micrometers in diameter, respectively) are small enough to penetrate the thoracic region of the respiratory system. The health effects of inhalable dust are well documented. Therefore, mitigating dust levels is imperative to protecting the health and well-being of the animals and the caretakers; and improving the environmental stewardship of cage-free layer farms.

Dust suppression test

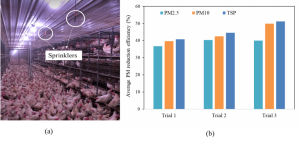

Spraying liquid agents onto the litter floor, such as tap water, acidified water, electrolyzed water, and mixture of water and soybean or canola oil, has been shown to reduce the dust level in poultry houses. In the Netherlands, researchers reported that spraying 3.6-14.4 gal. water onto 1000 ft2 litter floor reduced dust level by 18-64%, however it increased NH3 emissions by 21% to 65% in cage-free henhouses. Housing styles, management practices (e.g., litter access time), climatic conditions, and litter quality of cage-free housing systems in the US can considerably differ from those in Europe, which warrants evaluation of dust mitigation strategies under US production conditions. In Iowa, a sprinkling system (fig. 2-a) installed in a commercial cage-free henhouse (50,000 hens, 505 L × 70 W × 10 H ft) was tested for dust suppression in winter of 2017-2018. The water was sprayed at the dosage of 3 gal. per 1000 ft2 based on 0.4 inch (1 cm) litter depth, once-a-day 10 min before the bird accessed litter floor. The sprinkler (nozzle) had the pressure of 50 psi. The dust reduction efficiency was 37-51% without causing NH3 issues in the cage-free henhouse (fig. 2-b). Adjusting spraying dosage according to litter depth is necessary since the birds will mix the top and bottom of the litter during foraging and dust bathing in the cage-free house. In addition, the cost of dust suppression with a sprinkling system is among the lowest of existing methods. Combining the capital and operating cost gives a total cost of approximately 5-10 US cents bird-1 yr-1 for the 50% of dust mitigation.

Figure 2. The sprinkling system (left) and dust reduction efficiency (right, PM2.5 and PM10 are particulate matter with size smaller than 2.5 and 10 micrometers in diameter, respectively. TSP means total suspended particles).