Recent post on the UGA Extension Precision Ag and Irrigation Blog

By Luke Fuhrer, Cliff Collins, Sarah Beth Thompson, Glen Rains, and Wesley Porter

Spraying is an important pre- and in-season operation that can either make or break a crop. This operation can be costly if done correctly, and very costly if done incorrectly. The cost can be attributed to a monetary cost of chemical and fuel, however, it can become a waste of an operator’s time if not applied correctly, costing the crop by inefficient control of a pest and costing the environment, impacting the local ecosystem and watersheds.

Sprayer Calibration Methods

1/128th of an Acre Sprayer Calibration Step

1. Measure inter-nozzle spacing. For broadcast spraying, measure the distance between nozzles (from center to center of the nozzles), while for banded applications, use the band width in inches.

Measure of the inter-nozzle spacing showing an 18″ spacing

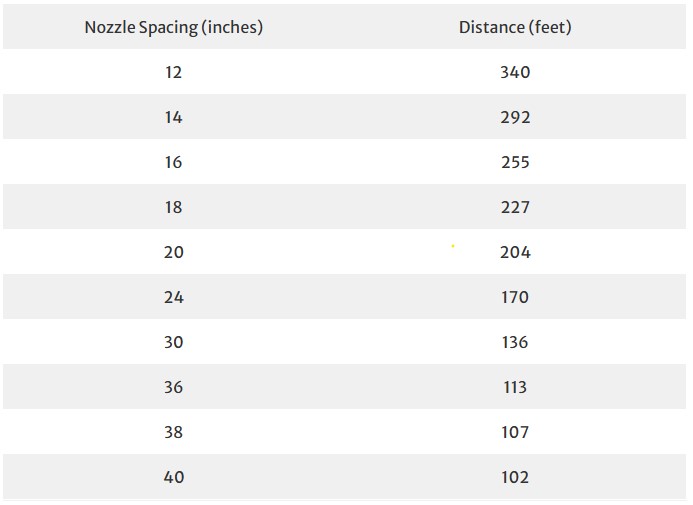

2. Using the measured spacing between nozzles, use the chart below to determine the correlated distance of travel to cover 1/128th of an acre at the nozzle spacing. To cover 1/128th of an acre, the tractor will need to drive the distance below and be timed to determine how long the spray volume will need to be collected for. Additionally, the other two charts below are the calculations corresponding to the time it would take for the tractor to cover the required distance. Thus, the operator can decide to either drive the required distance and record the time it takes, or use the table with the calculated travel times.

Nozzle spacing at the selected ground speed for spraying:

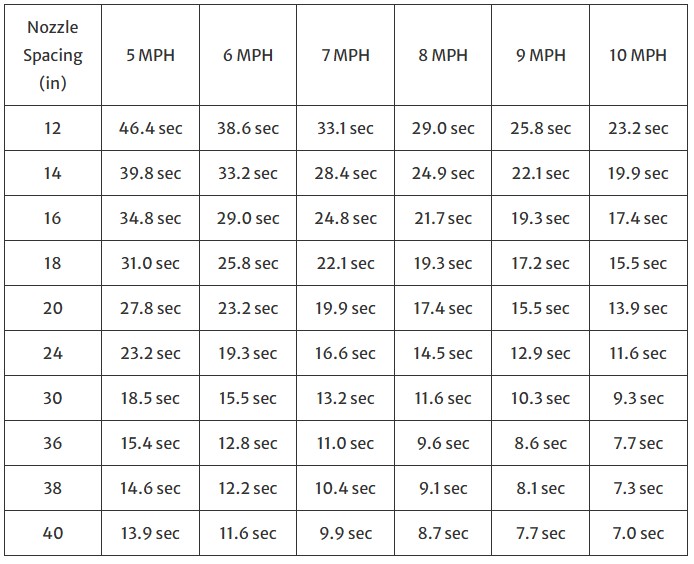

Table 1: Calculated catch time in seconds for combinations of nozzle spacings and speeds from 5-10 MPH.

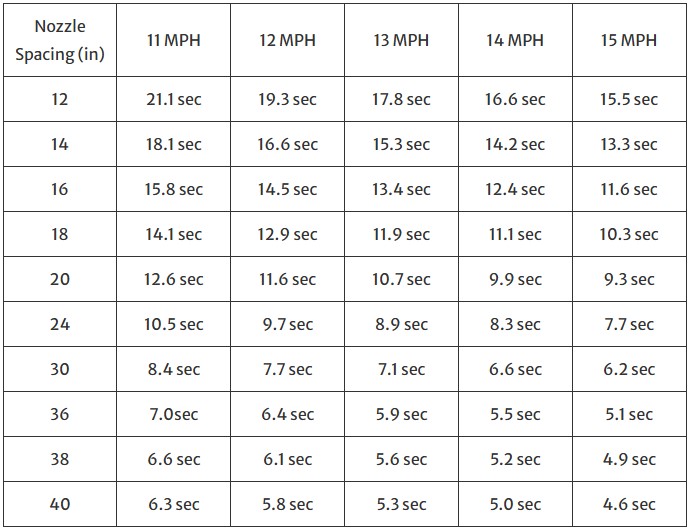

Table 2: Calculated catch time in seconds for combinations of nozzle spacings and speeds from 11-15 MPH.

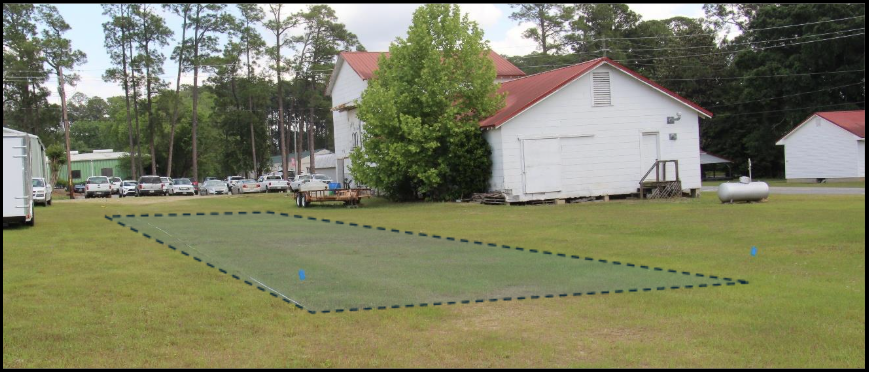

3. Measure the distance that the tractor will need to drive using a wheel tape, as the distances are all greater than 100ft. Make sure to lay this out in an area that is representative of the area to be sprayed. The sprayer must be calibrated for the environment in which it will be operated. Flag the beginning and the end of the distance so the operator will know when to turn the system on and off.

4. Have the tractor operator provide enough space before entering the target area, so the machine is up to the travel speed at which the spraying will occur. Have an individual prepared with a stopwatch to time the tractor from when it enters and leaves the area. It is recommended to do this at least twice and make sure the time it takes to travel this distance is correct.

Shown above: An incorrect starting point for timing, as the tractor will not be at a consistent operating speed during the timing.

Shown below: A demonstration showing to start the tractor a distance outside the target area to safely get the tractor to the correct operating speed.

If it is not desired to lay out the target area and drive the tractor through, while timing, Tables 1 & 2 below show the calculated catch times for a variety of combinations between nozzle spacings and tractor speeds. This table was generated using the above nozzle spacing and distance table, and some simple unit conversions.

5. With the time recorded for the tractor to drive the distance laid out, start the sprayer up, with only water in the tank, and allow the boom to fully prime and show a consistent and steady spray within the recommended pressure range of the nozzles being used. With the stopwatch in hand, catch the entire spray volume from a single nozzle for the time it took the tractor to drive the determined distance at the desired speed or the calculated time, which ideally should match.

Catch the spray volume of a single nozzle for the time recorded from the previous step.

6. Either using the collection apparatus or a graduated cylinder, measure the collected spray volume in fluid ounces and this will equate to the gallons per acre being applied. An example of this would be measuring 18 fl oz., which will equate to 18 gallons per acre being applied.

SpotOn® Sprayer Calibration System

The SpotOn® is a device that can be used to measure flow rate. Many of our agents currently have access to one of these systems if needed. To operate the SpotOn®, hit the front start button, wait until three hashed lines show on the screen, and then hold the apparatus below a single nozzle at a 10-15° angle as recommended by the manufacturer. Make sure to hold the device tightly to the nozzle to catch all the spray volume. Once water has filled the tube, a reading will show on the screen in the preselected units, usually gallons per minute (GPM).

Showing how to catch spray volume from a nozzle using the spot on, this is done at a recommended 10-15°.

5940 Equation

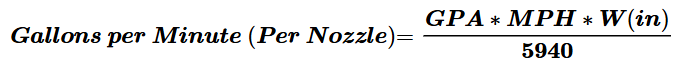

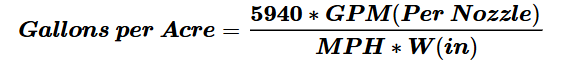

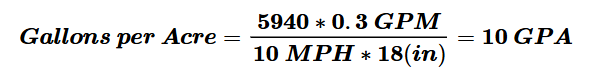

The 1/128th acre calibration method provides an answer in volume per area (gallons per acre), while the SpotOn® provides a rate of volume per minute (gallons per minute). To calculate between volume and rate, the 5940 equation can be used. This equation allows the user to leave the collected values in their respective units: GPA, MPH, W(in), and GPM, and calculate between the two measurements. Leave the measurements in their units; 5940 accounts for all unit conversions!

For example, working from the previous example with nozzles at an 18-inch spacing. If you caught 0.3 GPM from a single nozzle, and planned to travel at 10 MPH the math would be as follows:

Hopefully, as shown in this post, while sprayer calibration can seem daunting, it is an easy task if you take your time and follow the correct steps. It is strongly recommended that you check each nozzle, while I understand this can take a long time to complete, the implications can be detrimental. A nozzle that has the wrong tip, orifice, is leaking, stopped up, or any issue will leave a strip in your field that has been misapplied, greatly decreasing pesticide or fungicide efficacy.