The hot-fill-hold method, a thermal processing commonly used for sauces, requires minimum time and temperature conditions to ensure your product is safe for consumption. If you seek a process approval from EFST, our forms will ask for your hold time and temperature. Not sure how to answer this question? Follow the steps below!

What you need:

- A container with a lid. For example, the packaging for your food product.

- Scissors, or another tool, to pierce the lid.

- Digital thermometer.

- Stop Watch – the one on your phone will work.

- Paper and pencil.

Step 1

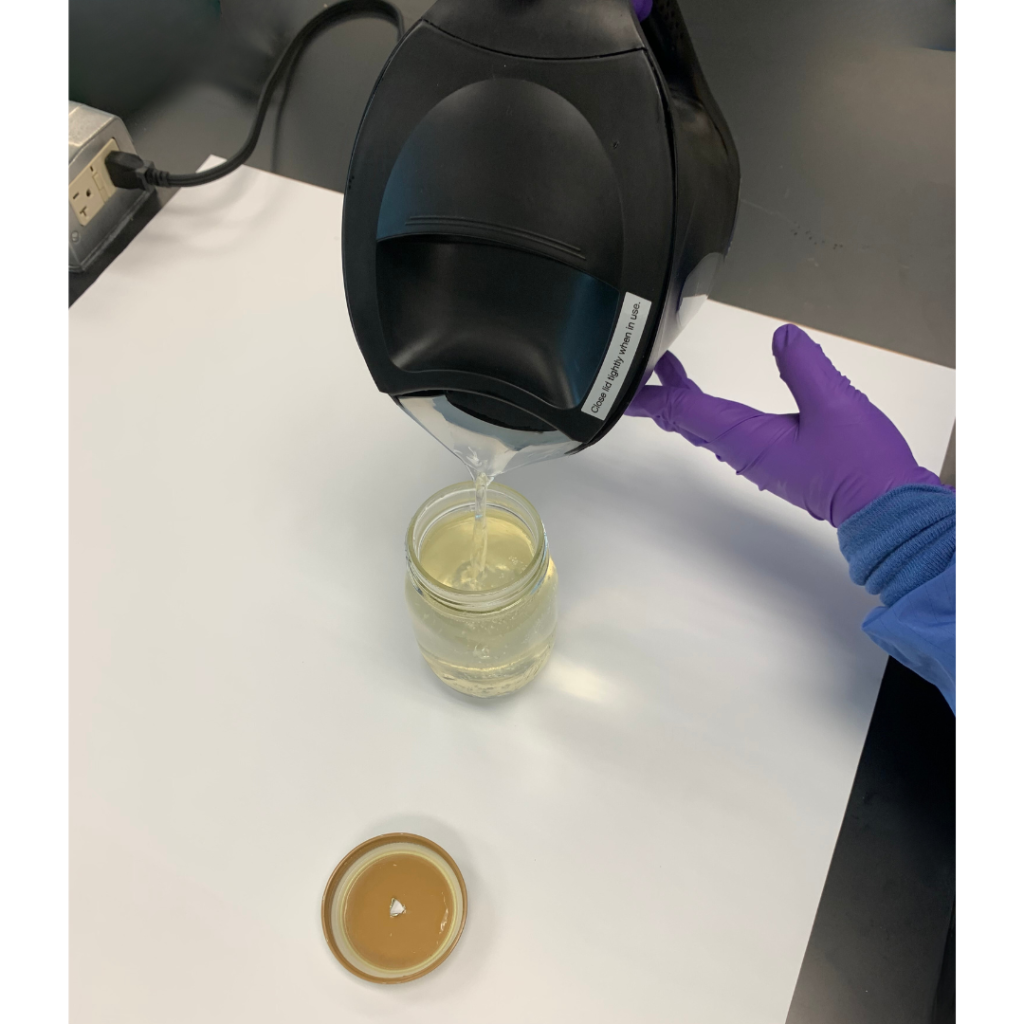

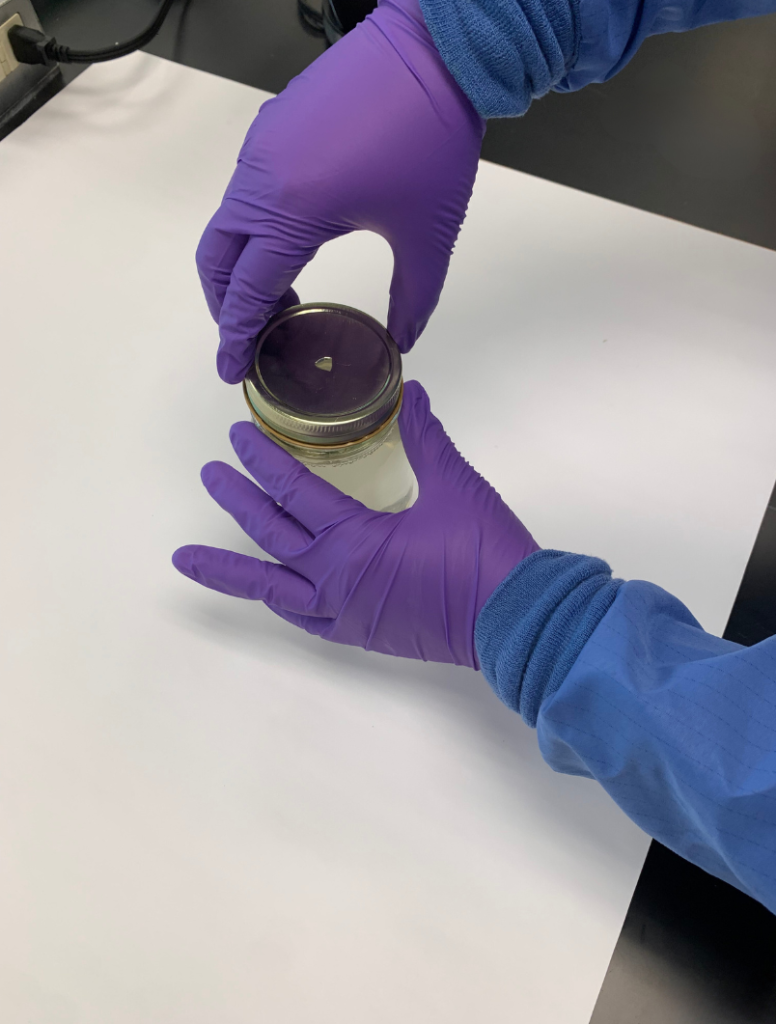

Prepare your container by creating a hole in the top of the lid (we used scissors). We encourage that you puncture the lid before you cap the container. The hole must be large enough to fit your thermometer.

Step 2

Step 2

Prepare your product according to your recipe. After cooking your product, fill the container and leave the typical headspace. Secure the lid onto the product.

Headspace is the void space above the product in a container.

Step 3

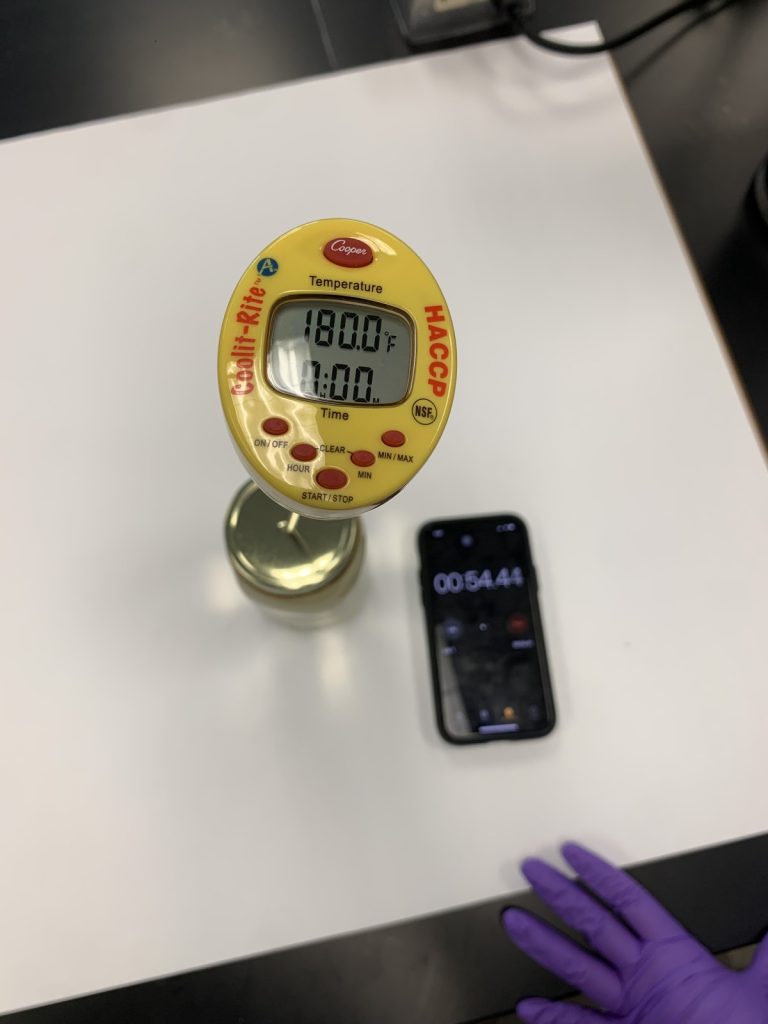

Insert thermometer through the hole in the lid, ensuring that the tip is in the geometric center of the container (i.e., halfway between the top and bottom, and halfway between the sides). Start the timer.

The temperature at the time the product is placed into the container is called the fill temperature. For example, our sample’s fill temperature was 180°F.

Step 4

Monitor the temperature for an appropriate time interval for your process. For fill temperatures above 160°F, we recommend taking readings every 15 seconds for 3 minutes. For fill temperature below 160°F, we recommend taking readings every minute for 10 minutes.

We recorded:

| Time, min | Temperature, °F |

| 0:00 | 180 |

| 0:15 | 179 |

| 0:30 | 179 |

| 0:45 | 178 |

| 1:00 | 178 |

| 1:15 | 177 |

| 1:30 | 177 |

| 1:45 | 177 |

| 2:00 | 177 |

| 2:15 | 176 |

| 2:30 | 176 |

| 2:45 | 176 |

| 3:00 | 176 |

Based on the recorded data, the temperature we recorded at 2 minutes was 177°F. Our minimum hold time is then 2 minutes and hold temperature 177°F.

All records for product must reflect at least this hold time and temperature, otherwise, this is considered a process deviation. Alternatively, using 178°F for a 1 minute hold time is valid.

We recommend repeating this experiment multiple times to obtain the best results.

Other Options

Follow steps 1-3, record your initial fill temperature, then take a temperature reading after 2 minutes. The temperature after 2 minutes is your hold temperature, as long as it is above 160F. Your hold time is 2 minutes. The hold time and temperature must be equal to or greater than the reference provided below.

Still have questions? Email us at efs@uga.edu or give us a call at (706) 542-2574. We are happy to review your data and discuss the best process for your product!

Tips & Resources

The higher the temperature, the shorter the time it needs to be held. Need help identifying minimum hot-fill-hold process requirements? Check out this publication from North Carolina State University to identify your minimum hold time and temperature for products with pH below 4.1. If your product’s pH is above 4.1, reach out to us for further assistance.