Wes Porter just sent out this update with some great tips and reminders when swapping your planter over from corn to peanuts.

By Marco Torresan and Wesley Porter

Even though it’s still early in the season, most of the corn has been planted and many producers are switching over and starting to plant peanuts. I have seen many farmers starting to plant peanuts, so hopefully they have already made these changes. As you finish up corn it is critical to take time to switch components over in your planter to ensure you maximize your seed placement and inherent germination and emergence in peanut. While some of these components seem obvious, when we are under a time crunch it can be easy to overlook simple things, so take your time and go through this list. The following provides a bulleted list along with some graphics of important components to consider:

- Components inside the seed meter:

- Seed plate

- Switch from your corn seed plates over to the peanut plates.

- Brush

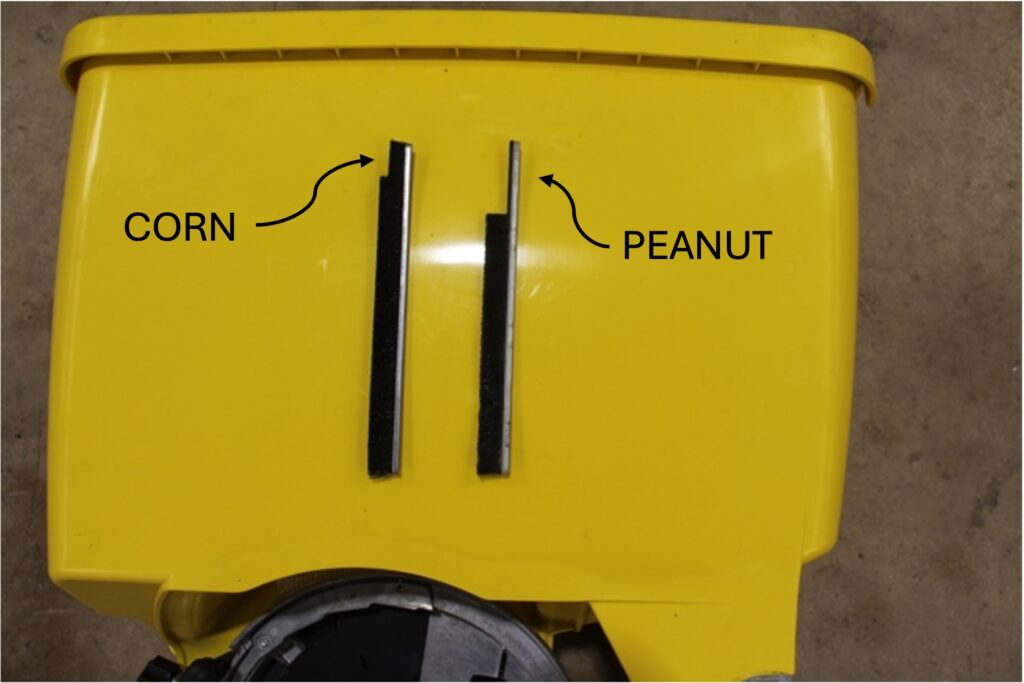

- The peanut and corn brushes are different, and the corn brush will not work with peanuts. The cut in the brush always goes to the top of the meter. As you can see in the pictures below, the corn brush has a very small cut allowing the corn seeds to pass by on the meter while the peanut brush has a much larger cut representing the larger seeded crop.

- Below is a picture of the peanut brush properly installed.

- Here is a picture of the corn brush properly installed.

- Baffle Position

- Larger seeding crops such as peanut will require a more open baffle position than corn and cotton etc. to allow increased seed flow. As shown in the image below, the left image has the baffle position all of the way closed, and the right picture has the baffle position all of the way open.

- Replace the vacuum seals if they are cracked or worn excessively.

- Doubles Eliminator Setting

- The doubles eliminator will need to be set less aggressive for peanut than for smaller seeds.

- Scraper/Knockout Wheel

- Check the condition of the scraper, and if you are using a knockout wheel, ensure that you have switched the wheel to match the appropriate crop.

- Seeding rate/sprockets

- Change your seeding rate or target population to ensure you are planting at the recommended peanut seeding rate, not your previous corn rate.

- Depth

- While the planted depth may be similar to corn, typically we want peanuts a little shallower than corn and need to shoot for closer to 2.5 inches deep. Check overall planter depth to ensure each row unit is at the appropriate depth.

- Please note that row units wear differently, so the same notch position might correspond to different depths across the planter row units.

- The optimal way to set depth is to sit the gauge wheels on a support that is 2.5 inches high (a piece of wood of that dimension works just fine or a planter Set-N-Seed or similar device Set-N-Seed – Planter Depth Calibration, Planter Depth, Set-N-Seed) and pull the depth handle as far as it can go. This way you can be 100% sure of the depth. You will be surprised to see that the notch position that corresponds to 2.5 inches depth might vary 1-2 notches across your planter row units.

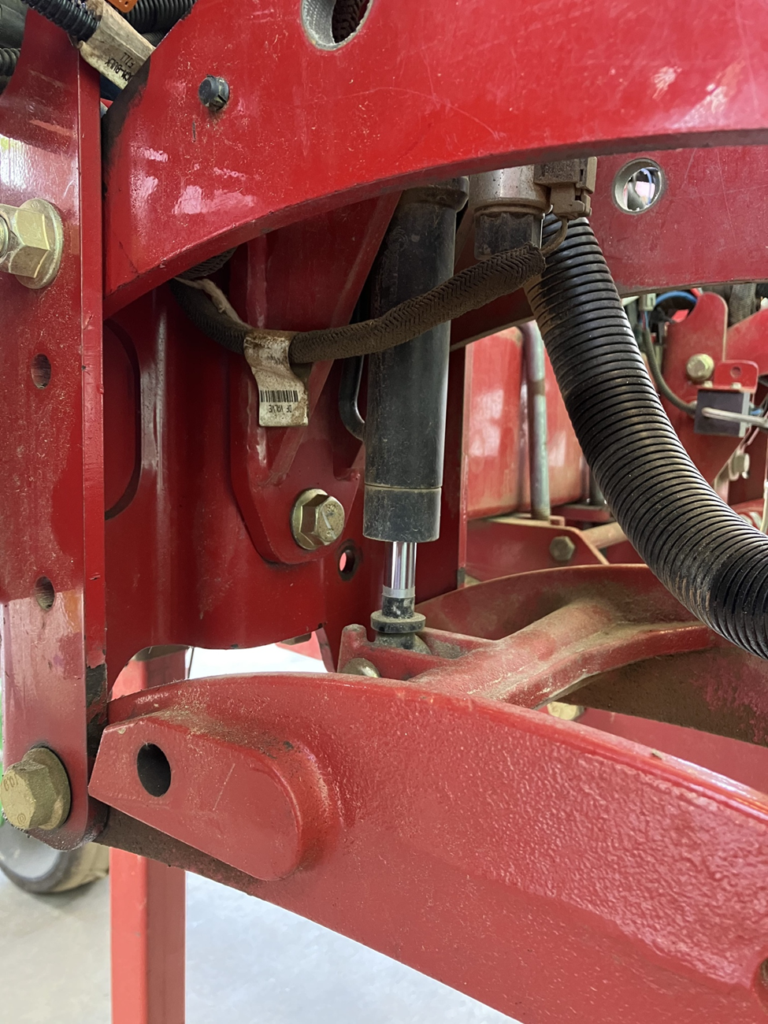

- Downforce

- Depending on condition downforce may or may not need to be changed but evaluate this field by field and when there are drastic changes to planting conditions such as soil moisture and texture.

- Increase the downforce when the set depth is not achieved or decrease it when the seeding trench is too compacted (as a rule of thumb, when the gauge wheels cannot be manually turned, the downforce is too high).

- If you have a hydraulic downforce system, make sure to calibrate the sensor before you start planting.

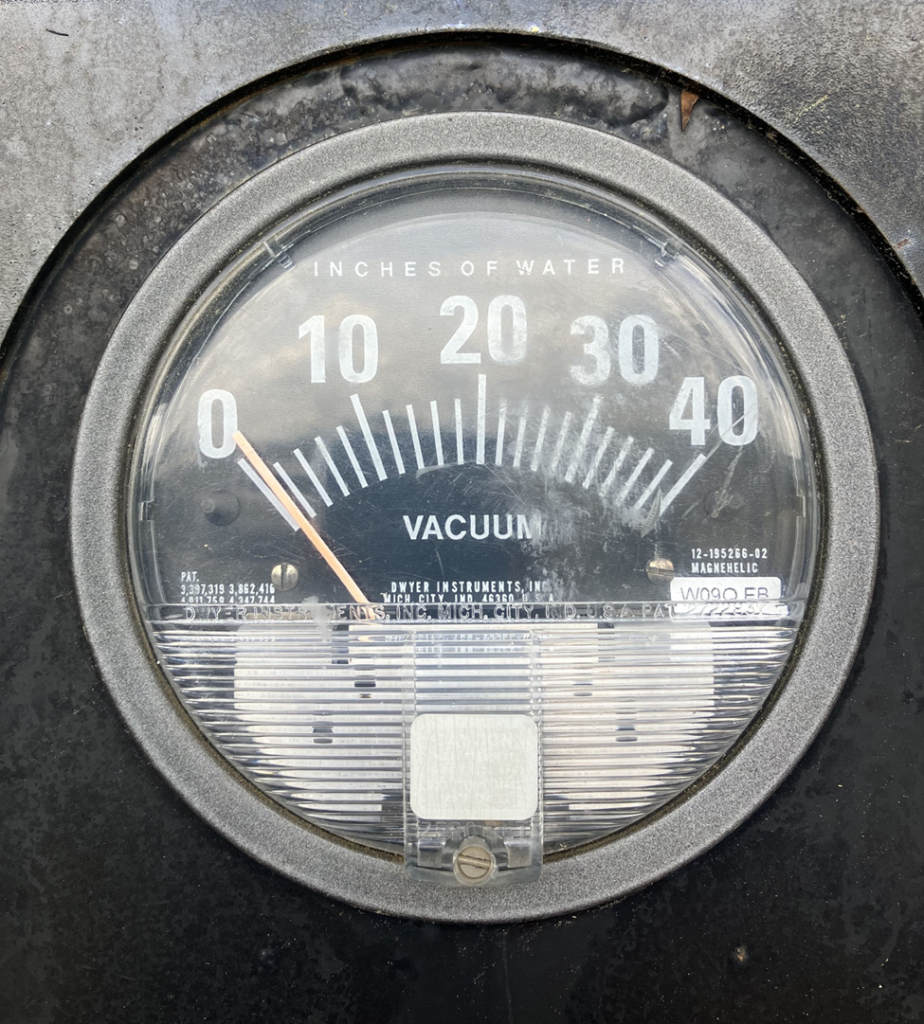

- Vacuum

- Read the manual to set an appropriate vacuum for your specific meter type and seed plate. Recent research has shown that vacuum level is especially critical in peanut planting due to the large seed size and weight, while not published this research has shown that increasing the vacuum level 25-50% above manufacturers recommended level for peanut helps to eliminate skips, and a proper doubles eliminator setting will reduce doubles.

- Planting Speed

- While we can plant corn at up to 7 mph without specialized delivery systems, peanut planting speed cannot be that fast. Recommended planting speed for peanut is in the 3.5 to 5 mph range. However, the performance of some planters begin to degrade above 4 mph.