Cage-free production and floor egg issues

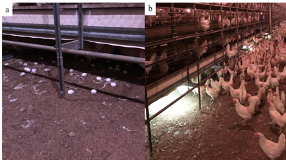

Poultry production (meat and eggs) provides cost efficient protein for human beings. Currently the U.S. is the world’s largest broiler producer (41 Billion lbs. in 2017) and the world’s 2nd largest egg producer (105 Billion table eggs in 2017). However, the U.S. egg industry is facing a number of animal welfare challenges regarding conventional battery cage systems. The primary fast-food chains and big-box grocers (e.g., McDonalds and Walmart) have pledged to source only cage-free eggs by the year 2025. According to the pledges, the market share of cage-free eggs will be increased from 24.5% in December 2020 to 72% by 2025 (Data sources: USDA Cage-free Shell Eggs reports, UEP, and Egg Industry Center). In addition, seven states have passed regulations to source only non-cage eggs by 2025 or earlier. However, cage-free production is not without its own challenges. The percentage of floor eggs could be as high as 10-15% on cage-free egg farms (Figure 1). Floor eggs must be collected manually by farm workers each day, which increases labor costs. Furthermore, floor eggs are at higher risk of contamination by bacteria (e.g., Salmonella) from litter/manure, which may trigger food safety concerns with the general public. Salmonella outbreaks are a potential issue within the egg industry and increased floors eggs could exacerbate the problem.

Figure 1. Floor eggs within cage-free hen houses

Floor egg management with light control

Lighting management has been used to reduce floor eggs in the cage-free production environment. A commercial cage-free layer farm in Iowa shared their successful experience in reducing floor eggs with lighting control. The light intensity beneath the aviary system is typically lower than the open floor areas and as a result layers tend to lay eggs beneath the aviary system. Figure 2-a was taken before installing lights beneath the aviary system, while Figure 2-b shows that lights were installed beneath the aviary system. The total number of floor eggs was reduced by up to 80% beneath the aviary system after light installation. However, many eggs were found in other places such as in the middle of open floor, and thus other methods (e.g., robots) may help with further reduction of floor eggs.

Figure 2. Effect of lighting management on floor egg reduction.

Floor egg collection with robots

The use of robots has been suggested to help reduce the amount of labor of poultry farm workers. Lab-scale studies on robotic applications on egg collection have been tested in different countries. In the Netherlands, researchers at Wageningen University designed a robot (PoultryBot, Figure 3) with dimension of 1.1 m L× 0.55 m W× 0.45 m H. According to their lab tests based on 300 floor eggs, the robot could collect 46% of eggs successfully. In the U.S., UGA poultry science researchers with collaboration of Georgia Tech engineers, have evaluated a French company’s robot (Tibot Technologies, Spoutnic) and improved the robot’s functions of egg detection, target approach, and egg pick up capabilities. The floor egg retrieval success rate reported is over 80% in laboratory or experimental cage-free housing tests.

Figure 3. PoultryBot developed by researchers at Wageningen University

Research has investigated the issue of floor eggs and the possibility of reducing the incidence of floor eggs in cage-free housing through lighting management and robotics. While commercially available robots are at affordable prices, applying robotics in poultry houses requires extra caution and an understanding of poultry housing systems, production situations, bird behavior, etc. Most previous studies have focused on egg collection instead of hens’ floor egg laying behaviors. Addressing bird behavior will be another area of study associated with floor laid eggs and the food safety issues that need additional investigation.