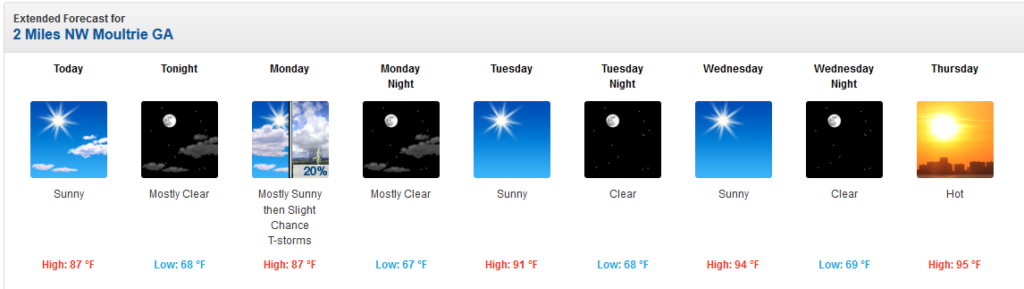

Last week was another exciting one in Colquitt County agriculture. Growers in the area have begun to harvest peanuts and defoliate cotton this past week. The five day forecast for the Moultrie-Colquitt County area is dry and sunny, which is great for the cotton and peanut harvest that is starting.

The September edition of the UGA Cotton Team newsletter is below.

Peanuts: The peanut harvest is starting in Colquitt County. Hull scrape clinics continue at the Colquitt County Extension office. Georgia 06G is running an average of 145 days to maturity. Hull scrape maturity clinics are held every Tuesday, Wednesday, and Thursday stating at 8:30 am. These clinics are held at the Colquitt County Extension office.

If I am close to digging how do I manage leaf spot? If two-three weeks out from digging, assess your field for disease. If leaf spot is not a problem (and white mold is not) then you may not need the sprayer in the field again. If leaf spot is in the field and not too severe, you might consider a last application. If you have lost 25% of your leaves, anticipate digging within two weeks, regardless of maturity. If you have lost 50%, you may have a week or 10 days max. 75% or more- the pods are likely dropping off now.

A critical consideration for choice of fungicides late in the season is that pre-harvest intervals (PHI) vary among fungicides. For example, Alto has a 30-day PHI, and Elatus and Convoy have 40-day PHI, compared to 14-day PHI for other fungicides such as Provost Silver and Fontelis. Growers must always check the label to make sure on all of these.

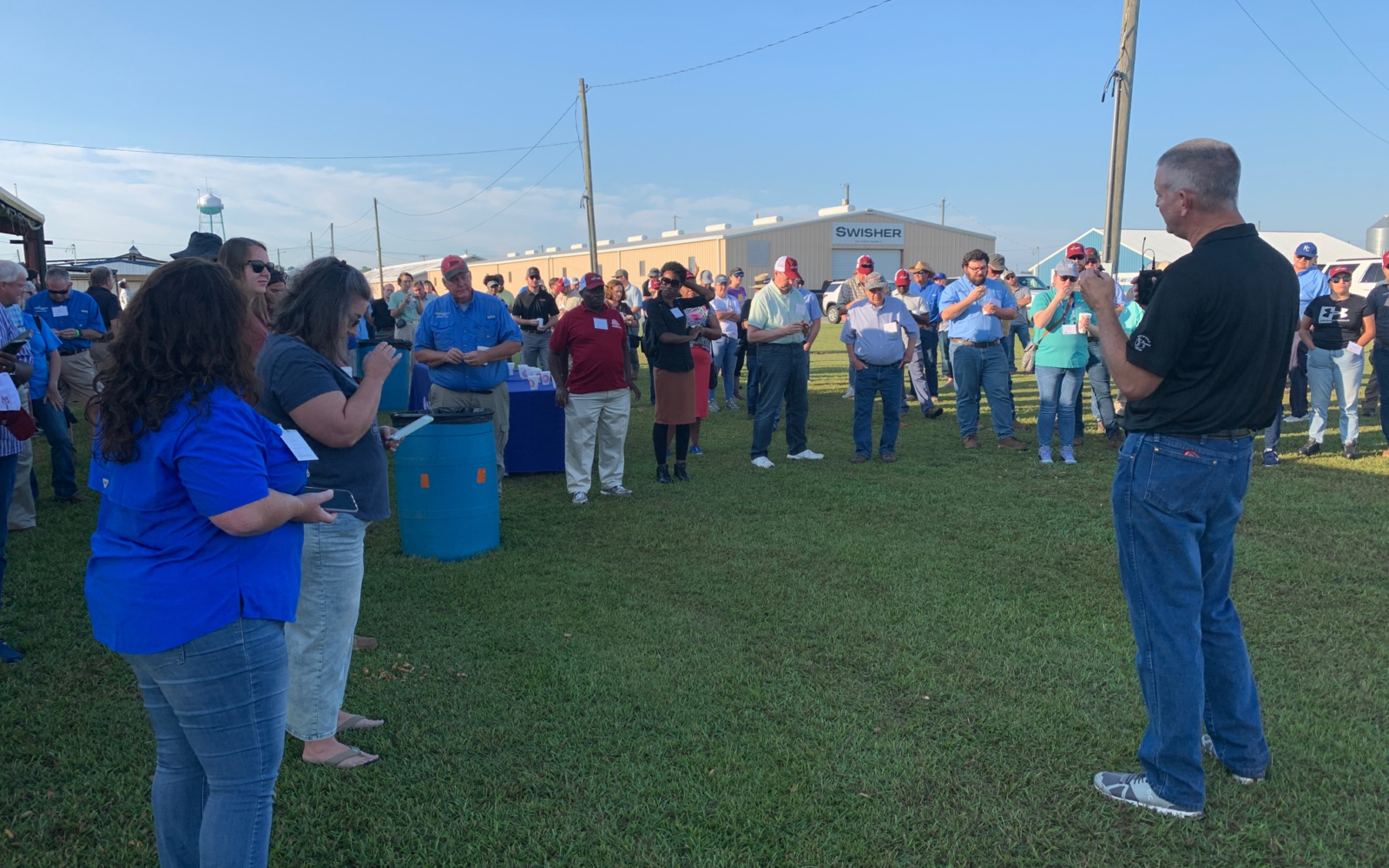

The Georgia Peanut Tour: The Georgia Peanut Tour was in Colquitt County this past Thursday (9/15/22). The Sunbelt Ag Expo hosted the tour which consisted of around 200 people. Participants were not only from the United States but from around the world. This stop would not have been possible without the help from Ameris Bank, Sunbelt Ag Expo, Cale Cloud (Grady County Agent), Sydni Ingram (Thomas County Agent) and the Moultrie Police Department.

Cotton:

Cotton defoliation time has arrived in Colquitt County. 2022 has been a challenging year for area producers. This year producers have had to face challenges such as increased input prices, whitefly, and crazy weather. Dr. Bob Kemerait, UGA Plant Pathologist, reminds us that we are in the fourth quarter of this production year. Cotton growers still need to get through cotton defoliation and peanut producers need to issues such as late leaf spot and harvest timing. Below are a few words from Dr. Camp Hand about cotton defoliation. This is from the September edition of the UGA Cotton Team Newsletter.

Defoliation Considerations for 2022 (Camp Hand): As we roll into September, it is time to start thinking about defoliating our cotton crop. As I have driven around the state in the month of August, I have already seen a number of fields ready to defoliate, particularly dryland fields in Southwest Georgia that were planted in late April/early May. I know that the weather in the past few weeks has put a damper on the crop as a whole, but it is time to start preparing for defoliation and harvest. Generally, I would say that the crop has been trending early, especially if you planted in May, so the best thing you could do is get out and look at your crop to make sure you defoliate at the right time. I’ve heard multiple growers this year say something along to the effect of they have never spent as much money on a cotton crop as they have in 2022. With that being said, my mindset is let’s get this crop defoliated on time, harvested in a timely manner, and on the gin yard so our growers can get paid on this crop.

There are a few things I have been talking about as I venture around the state talking about defoliation, and some of the high points are below:

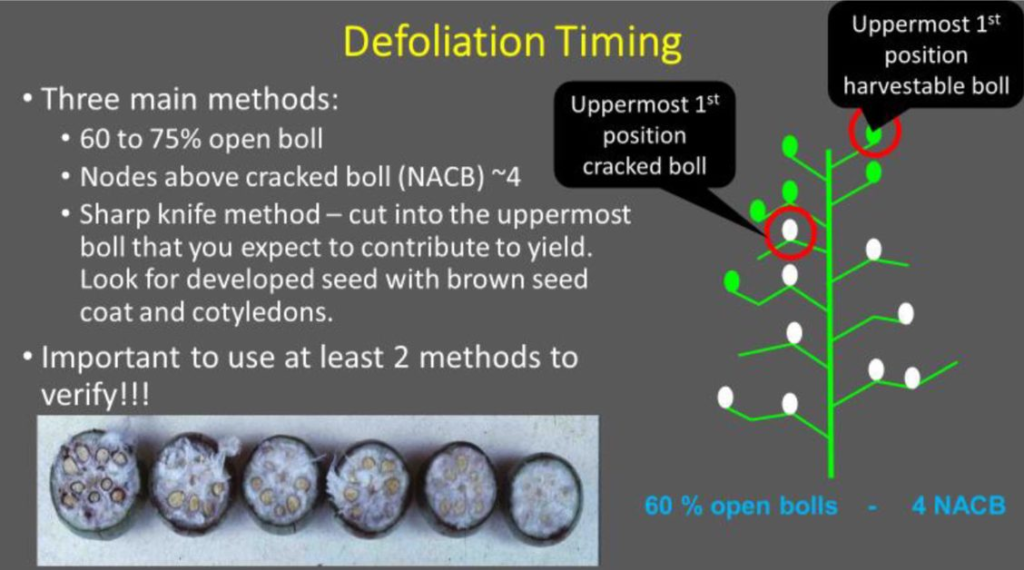

1. Make sure the defoliation “trigger” is pulled at the right time. There are many ways to determine the appropriate time to defoliate your cotton crop – 60 to 75% open boll, 4 nodes above cracked boll (NACB), and the “sharp knife” method. It’s always good to use two methods to determine the correct timing as a way to double check yourself. To determine % open boll, count the number of open bolls, the number of unopened (harvestable) bolls, divide the number of open bolls by the total bolls and multiply by 100. For NACB, count the number of nodes from the uppermost first position cracked boll to the uppermost first position harvestable boll. When that number is 4, on average you are good to pull the trigger. And lastly, for the sharp knife method cut into the uppermost boll you intend to harvest and look for a black seed coat with developed cotyledons inside, and you want the lint to string out.

2. Make sure you are using the correct products and rates to accomplish your intended goals. There are 3 main goals in defoliation – leaf removal (juvenile and mature leaves), regrowth prevention, and boll opening. Determining which goals you are trying to accomplish, as well as the environmental conditions surrounding defoliation, will assist in the decision on products and rates. For regrowth control and juvenile leaf removal, thidiazuron containing products will be needed in the tank mix. Thidiazuron alone is available under many trade names (Dropp, Freefall, Klean-pik, etc.), and there is also a premix of thidiazuron + diuron (Ginstar, Cutout, Adios, etc.). Mature leaf removal can be accomplished with a number of products. The main one utilized in Georgia is Folex (tribufos), but there are a number of PPO inhibiting herbicides that can be utilized as well (Aim, ET, Sharpen, Reviton, Display, Blizzard, Resource). Lastly, your boll opening products contain ethephon. Whether it is ethephon alone (Boll Buster, SuperBoll, Setup, etc.), ethephon + urea sulfate (Cotton Quik, First Pick), or ethephon + cyclanalide (Finish), these will all open bolls.

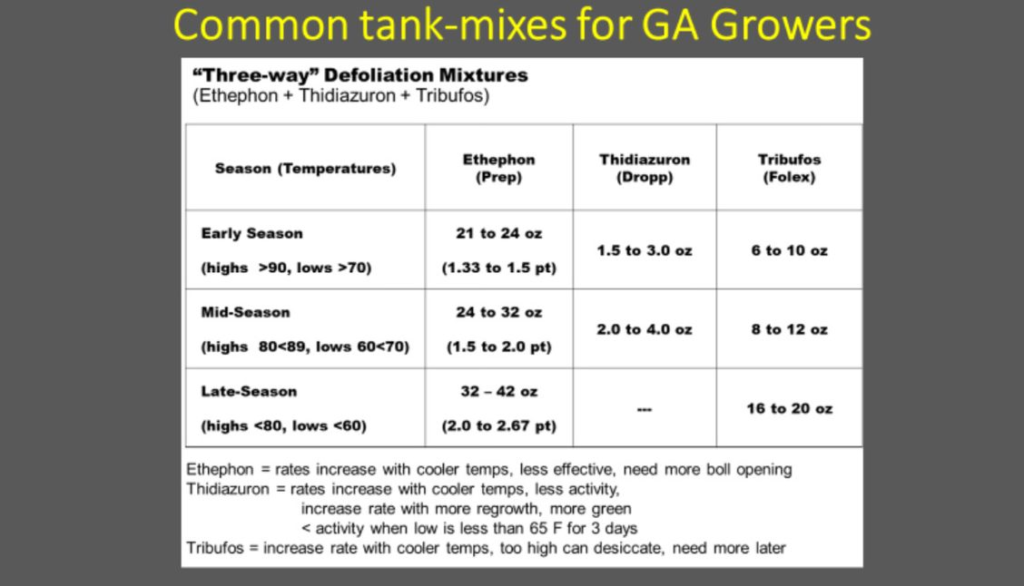

The most common tank-mixture utilized by Georgia growers includes thidiazuron (Dropp), tribufos (Folex), and ethephon (Prep). Below is a table to assist in rate selection for each product from early to late season.

For ethephon and tribufos, as the season progresses and it gets cooler, rates should increase to get the desired effects. Whereas once we get to the end of the season, thidiazuron is removed from the tank-mix because as it gets cooler outside there is a lower risk of regrowth. Keep in mind that you can substitute tribufos for any of the aforementioned PPO inhibiting herbicides, and I would follow the same trends with rate selection (lower rates when it’s warmer outside, increase as it gets cooler). Recommended rates on each product discussed here throughout the season can be found beginning on page 148 of the 2022 UGA Cotton Production Guide, which is at the following link: http://www.ugacotton.com/production-guide/. Also, I will be in constant contact with our UGA County Extension agents throughout defoliation and harvest season, so if you have questions about products or rates feel free to reach out to your local UGA County Extension Agent.

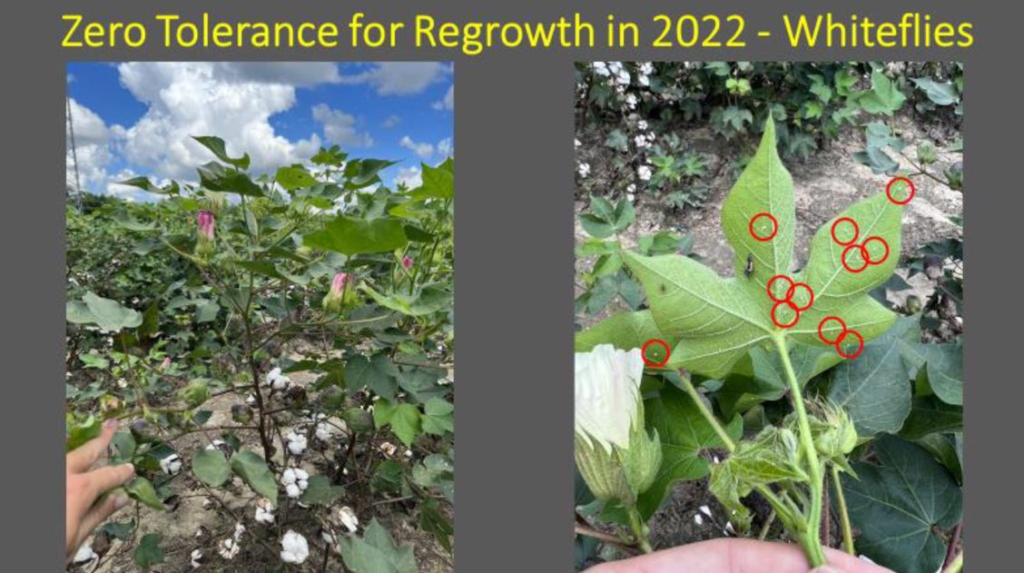

3. Zero Tolerance for regrowth in 2022!!! Dr. Phillip Roberts has already discussed this in his newsletter entry, but keep in mind that one of the best things you could do to manage whiteflies in 2022 and assist in management for 2023 is defoliate your cotton crop in a timely manner. Below is a picture I took in some plots in Tifton. It is clear that the bottom crop is ready to defoliate, but with recent rains it has started regrowing and blooming. While many would try to “put a top” on this, we decided to defoliate it. Investing more money to try to make a top crop doesn’t seem worth it for a couple of reasons – first, we have enough money tied up in this crop as it is, and waiting on that top to finish will cause the bottom crop to deteriorate. Let’s get what’s there and call it a year. Second, if we let that regrowth keep going, that young growth is like cotton candy to whiteflies (circled in red below). They will keep feeding and reproducing there, and will contribute to the population going into the winter time and consequently into next year. Let’s defoliate this crop in a timely manner.

4. One shot vs. two shot – what are the benefits? I get this question a good bit during defoliation time. In Georgia, we primarily use 1 shot for defoliation and it works very well. Rarely will I ever recommend a second shot unless something went wrong on the first. So keep in mind the amount of money already invested in this crop – a second shot at defoliation means more chemical costs, as well as diesel fuel/application costs. Let’s get it done right the first time and get the crop out in a timely manner.

5. Mo’ water is mo’ better. A higher sprayer output (gallons per acre) works better than a lower sprayer output with respect to defoliation (even if you decide to use dicamba nozzles). Let’s shoot for 15 GPA if you’re defoliating with a ground rig to get defoliant down in the canopy.

6. KEEP DEFOLIANTS ON TARGET!!!! I talked about this a lot last year. It is imperative that we apply all pesticides responsibly, let’s not forget that at the finish line. Keep the lessons from Using Pesticides Wisely trainings at the forefront of your mind as we apply all pesticides, including defoliants. Keep in mind what is around your fields, the wind speed and direction at the time of and after application, keep the spray booms 24” above the crop canopy, and use nozzles that produce larger droplets with a higher spray output. It is important from the aspect of reducing pesticide drift in general, but also from the standpoint of protecting the chemistries we use. You have likely heard myself and other specialists discuss the petition submitted to the EPA to revoke all tolerances and cancel registrations for all organophosphate pesticides. On the lists of pesticides included in the petition are a lot of important ones – acephate (Orthene), dicrotophos (Bidrin), phorate (Thimet), malathion, and many others. But one of the most common defoliants in used in the cotton belt, tribufos (Folex), is also on that list. It is of vital importance that we apply Folex and these other pesticides responsibly so that we will have them in the future. If you would like to submit a comment to the EPA stating how important these chemistries are to you and your operation, please contact your local UGA County Extension Agent. They all know how to do this, and I promise that the EPA reads these comments and values input from producers.

7. Timely defoliation and harvest are key to producing a high-quality crop. Only defoliate what you can come back and harvest in about 10 to 14 days. This helps preserve crop quality and can reduce the likelihood of an extraneous matter call. And speaking of extraneous matter, handle your modules carefully and be sure to get grocery bags/balloons out of your field prior to harvest to reduce the likelihood of plastic contamination. It’s a 2X deduction from the classing office and our friends at the gin don’t like plastic. Let’s do our part to reduce plastic contamination.

I hope that everyone has a safe and prosperous defoliation and harvest season. As always, if you ever have questions or need anything please don’t hesitate to reach out to your local UGA County Extension Agent. They, along with us specialists, are here to help!

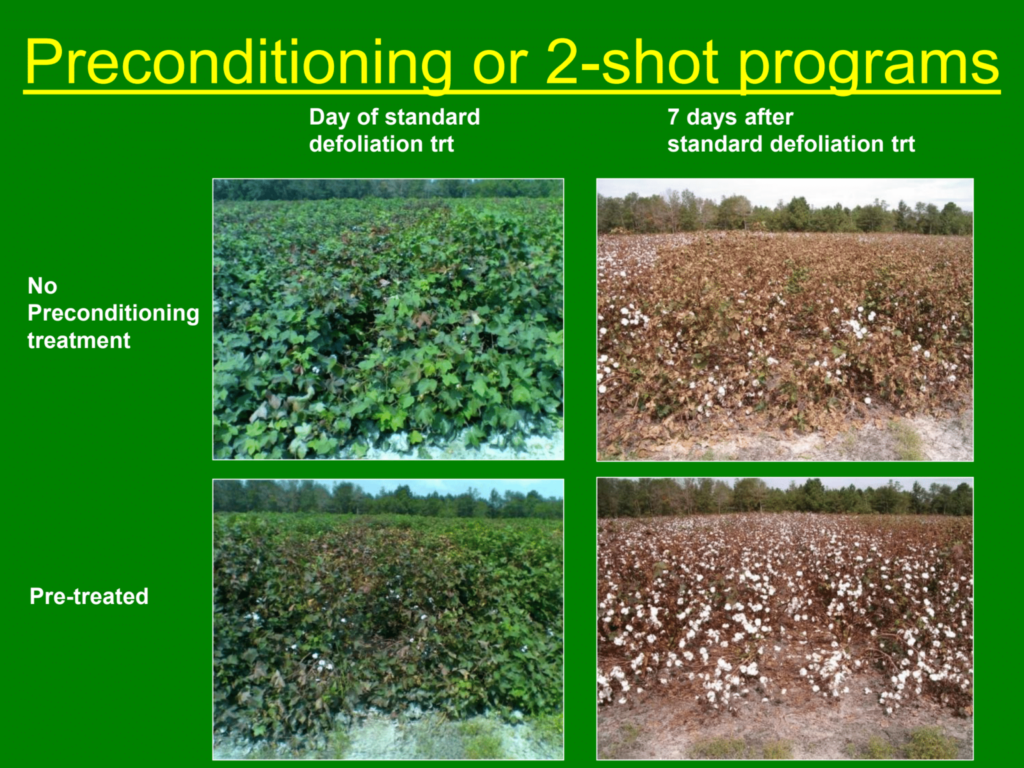

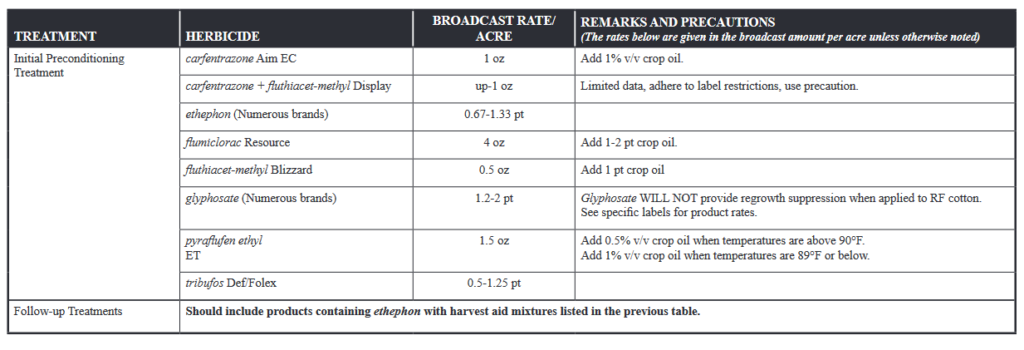

What about preconditioning cotton? I have received a question or two about preconditioning cotton from a couple growers this past week. Fields with a dense canopy of foliage and significant numbers of green bolls may require two applications. The goal is to remove much of the foliage with an initial application, exposing un-open bolls to sunlight and improving air circulation within the canopy. The follow-up application should be made 7-10 days later when sufficient leaf drop has occurred to allow spray coverage with boll opening products containing ethephon. However, premature preconditioning

or defoliation may increase the risk of halting development of younger or immature

bolls, rendering them unharvestable.

Packer Park Field Day.

There was a great turnout for the Packer Park Field Day last week (9/12/22). Dr. Bob Kemerait, UGA Plant Pathologist, was on hand to discuss some key aspects of nematode management, fungicide timing for areolate mildew and end of the year disease management tactics. This field day could not have been possible without the support of Colquitt County Young Farmers, Phytogen Cotton Seed, Bayer Crop. Science, Dynagro Seed, Corteva and AgLogic.

Dr. Bob discussed topics such as nematode management, and aerolate mildew. He also brought up the point that long range forecast shows that there is a strong likelihood that La Nina will continue through 2022, with a return to neutral conditions likely by spring. That means that even though the tropics are quiet now, we expect them to ramp up soon and the next few months could be interesting from a tropical standpoint. It also means an increased chance of warmer and drier than normal conditions in the Southeast, especially in the southern half. Warmer winters mean a great chance nematode populations will be higher in the spring. If you would like more information on this subject please go HERE for a blog post by Pam Knox.

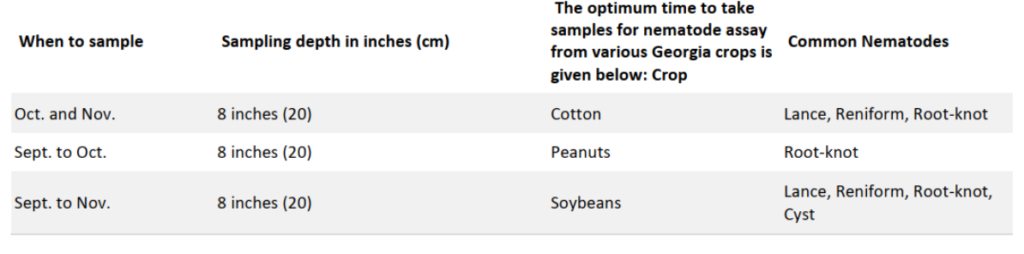

Dr. Bob also talked about nematode sampling. September-October is the Ideal Time to Take Nematode Samples!! Now is an ideal time to troubleshoot those problem areas in a field. Nematode populations should be at a peak now (when you can still identify the problem areas) or shortly after harvest. We have good moisture now which makes for good nematode samples. Take the nematode samples in the root zone and make sure they don’t dry out before mailing. You may want to send off a soil sample also to make sure pH or low nutrient levels are the problem.

Sampling Nematode Procedure

Properly taken samples from small field units can reduce production costs by allowing the grower to eliminate nematode control practices where they are not needed and implement control practices where they are needed. Improper sampling can lead to poor recommendations and economic losses which could have been avoided.

Both large areas and small areas should be sampled in a systemic, zigzag pattern. As nematodes may not

survive in upper 1-2 inches of soil due to extreme environmental conditions (hot and cold), first remove upper soil layer and then take samples using a 2.5cm (1-inch) diameter soil probe. Take 20-30 soil cores in a zigzag pattern from regularly spaced locations throughout the field or area of concern (4-5 acre section). From each sample about 1 pint (1/2 liter) of soil should be transferred into a labeled plastic bag for nematode assay. Once sampled put in a zip-lock type bag and keep cool. Keep the sample out of direct sunlight preferably in a cooler. Label the plastic bags with sample number location and date of sampling. The assay forms are available the local Extension office.

Below is an interesting article from Dr. Steve Brown, Alabama Extension Cotton Agronomist, about observations that can be made at the end of the year to help increase yield next year.

5 Minutes to Increased Knowledge about Cotton Management. Ok, we all hear offers and gimmicks about easy steps to this or that. Many such plans turn out not to be so easy or not to deliver the advertised results. As a simple way to greatly add to your understanding of cotton – how it grows, what it takes to make yield, where that yield is produced, etc. – I suggest you set aside 3 to 5 minutes for a humble activity. You’ll get a little dirty, and it might make seniors like me a little stiff.

Sit or kneel down in between two rows of mature cotton, preferably at 30 to 40 percent open or thereabouts. You don’t have to write anything down, though you can. You are basically in the canopy to observe and see the results of a season of growth and management. Look at the stand and estimate the number of plants per foot. Note any skips and how that affects stalk size (diameter), branching and lower canopy fruit counts. Conversely, where 2 or more plants are planted in a hill or in close proximity, observe what that does to stalk size and fruit counts. Assess the overall plant canopy. For leaves still present, inspect them for symptoms associated with nematode damage (you will have to look at the uppermost canopy to see the yellow “tiger stripe” symptoms that suggest rootknot nematode) and foliar diseases such as target spot and areolate mildew. Is the canopy still green and is there significant basal (from the stalk) or terminal regrowth? What is the approximate node of the 1st harvestable boll? See how many rotted or hard locked bolls are in the lower canopy. What is the approximate node of the last harvestable boll? Of potential fruit sites, how many harvestable bolls are present? Estimate that percentage. Does it approach 50 percent? For at least one representative plant, count the nodes and determine the node of the uppermost harvestable boll and the number of total nodes. Don’t over count juvenile green terminal regrowth if it is present. Are there any vegetative bolls, those produced on lower, non-fruiting branches that essentially become secondary terminals? Are they comparable in maturity to other bolls up the stalk? Again, this is a look and learn exercise requiring no more than a few minutes.

From these few observations, you should: See the effects of plant population on cotton growth, development, branching, stalk size/strength, and fruit distribution, all of which will sharpen your thoughts about seeding rates and overall management. Think about fertility, especially N rates. A tall, aggressive, possibly still-green canopy and strong regrowth with a half open boll crop could suggest excessive N. At the other end of the spectrum, total, premature leaf defoliation probably indicates challenges with K or possibly, severe target spot. Examine overall fruit retention. Get a sense of where the bulk of the crop is produced within the lower, middle and upper parts of the canopy and even on vegetative branches. When final boll set is compared with the final yield, you will appreciate the significant compensatory capacity of cotton. A count shows how many nodes are required to make a crop and the contributions of each potential zone. These bits of information also point to where your pest management focus should be most diligent and may also guide your thinking about how long to carry the crop before termination. Over the past week, I’ve spent hours on my knees and backside doing this very thing in research trials. I am surprised to see how few upper bolls contribute to overall yield and the sporadic number and immaturity of vegetative bolls. Boll size seems smaller this year, which perhaps (?) doesn’t bode well for big yields. I’ve observed less hardlock and boll rot than anticipated. I’ve seen stands where cotton is a “weed;” in other words, there would be a good stalk, good stalk, and then a thin, spindly stalk that had little fruit.

I commend this simple exercise to any who grow or manage cotton. Not fun unless you make it brief, but so informative. (Brown)

If you have questions or comments please contact the Colquitt County Extension office.

Have a great day..

Jeremy M. Kichler

Colquitt County Extension Coordinator